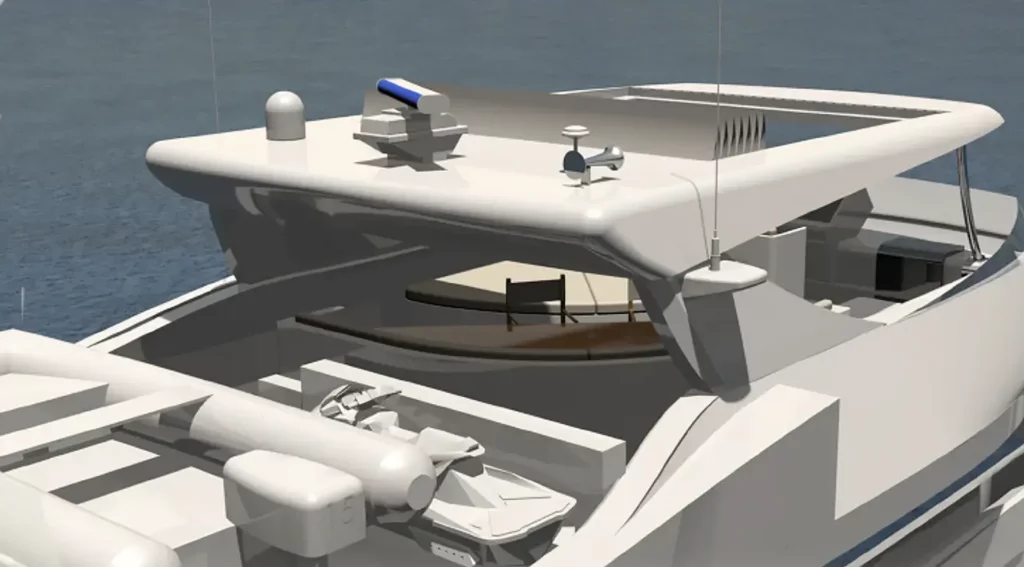

From design to implementation and installation on board, the creation of a hard top for a Falcon 90 was entirely managed by Technicomposit. This project began with a 3D architectural drawing to ensure precision and a perfect fit with the yacht. A wooden framework was built for the mould, carefully shaped to the required dimensions of 7.5m x 5.30m. Once the mould completed, a gelcoat was applied using a spray gun, followed by the lamination of the piece in carbon composite, a material chosen for its lightness and strength.

Vacuum lamination ensured a strong, uniform finish, reinforced by strategically placed carbon fibre reinforcements. The hardtop, which incorporates a retractable soft top for maximum flexibility, is attached to the old roll bar and two stainless steel pillars at the front, ensuring a stable and durable installation. The addition of LED lighting around the opening, with a dimmer system, provides a customisable and elegant ambience.